How Sage's Carbon Fiber Fly Reels Are Made

Form follows function. Like fly fishing, reel design represents the marriage of art and science. Field experience informs innovative engineering, and hours spent on the water are backed up with hours in the lab to ensure that every Sage reel lives up to our brand promise of perfecting performance. Each reel we create is unique, not only between series but within the series, as each size is tailor-designed with the appropriate clutch bearings, drag discs, hub size, and shaft diameter.

How Does a Fly Reel Work

PRECISE CONTROL

If your reel doesn’t provide control, it’s just an expensive line holder. For over 30 years, we have been the leader in innovation of reel design and engineering. Knowing control is paramount, we modernized drag systems for consistency, durability, and dependability. We create structural integrity through design, allowing us to increased strength and decreased weight. We focus on the angler’s experience, the confidence in adjustments, the ease of use, and the ease of maintenance.

SEALED CARBON SYSTEM (SCS) DRAG

With its smooth engagement and consistent, dependable, and repeatable pressure, our SCS Drag allows you to fish with confidence knowing your tippet is protected. Proprietary high-grade US made carbon easily and repeatedly handles high pressure and quickly dissipates the kinetic energy of that running fish into thermal energy. Tailored configurations allow us to create specific drag systems for each model, size, and fishing application, and the entire system itself is sealed to keep out water, sand, grit, and salt.

ONE REVOLUTION DRAG KNOB

Numbered settings, detents, and audible clicks help you take the guesswork out of setting your preferred control level. Our SCS Drag is hand-calibrated for precision and consistency, allowing for repeatable settings and confidence in your adjustments. The easy switch between decreased tension for stripping and increased pressure for fighting fish makes for more time fishing and less time setting drag.

LARGE/CONCAVE ARBOR DESIGN

Our large arbor designs allow for faster line retrieval and reduced line coiling. More importantly, it creates a consistent drag. The large arbor diameter means the overall diameter from which the line is removed does not decrease significantly so the change in drag resistance is minimized. Our concave arbor design creates a curved surface that increases structural integrity. The result is a drastically improved strength-to-weight ratio, meaning we can put less into the reel so you can get more out of it.

PREMIUM MATERIALS

Performance demands quality, and that begins with the exceptional materials we use to build our reels.

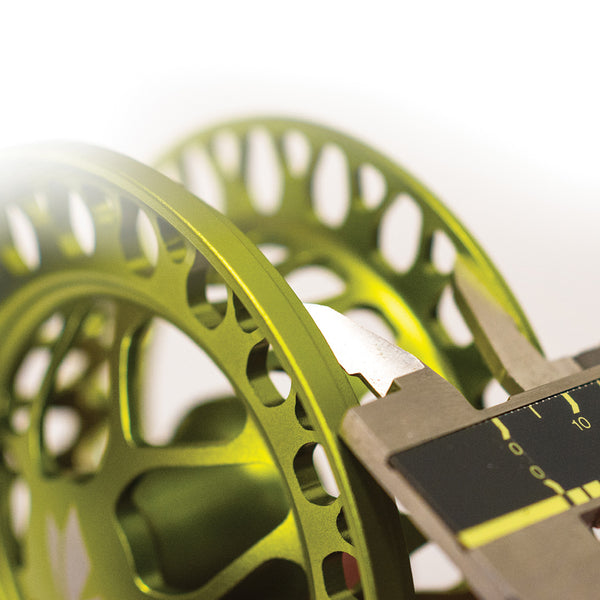

COLD FORGED ALUMINUM

We start with 6061 aerospace grade aluminum, known for its incredible strength-to-weight ratio and machining and finish qualities. We then cold forge and temper the aluminum, adding strength and rigidity while pre-shaping the metal for the frame and spool. After precision machining on state of the art CNC centers to our exacting tolerances, the aluminum is anodized for surface protection, corrosion resistance, and durability.

EXCLUSIVE USA CARBON

Our drags discs are made with proprietary, high-grade US made carbon, the same material used in the brakes of jets and F1 race cars. We utilize carbon drag systems because we recognize it is the most efficient material for dissipating extreme heat without wear. Unlike alternative drag components such as cork or plastic, or even polymers like Delrin® and Rulon®, carbon does not compress, deteriorate, melt, or burn. It allows us to create compact drag systems that are high performance, stable, durable, and repeatable.